Our hygiene solutions

Hygiene in the food industry

Current hygiene regulations are based on European and German law, compliance with which is monitored in Germany by, among others, the public health department. Food processing companies are obligated to ensure that food and beverages are free from contamination.

As part of their self-responsibility, these companies must conduct internal controls according to the principles of the HACCP concept (Hazard Analysis and Critical Control Points). Hygiene training for employees and clean working practices are fundamental to this in the food and beverage industry.

Particular care must be taken when handling food, as inadequate hygiene can pose an immediate risk to consumers. Insufficient hygiene can lead to the transfer of bacteria and other contaminants to food or equipment used in production and processing. These contaminants find ideal growth conditions on a wide variety of surfaces and multiply rapidly.

Hygiene in hotels and restaurants

Hygiene plays a crucial role in the hotel and restaurant industry, as many establishments produce ready-to-eat food themselves or market it on-site. This generally applies to chain stores or concept-based businesses, but also to all types of food service establishments and hotels. Products are served to customers on-site and often consumed immediately. Hotels and restaurants must therefore meet particularly stringent hygiene and safety standards.

To ensure compliance with these strict hygiene measures, HyServe offers various rapid tests that provide information about the current hygiene status of surfaces, for example, after cleaning. As part of food safety, worktables and equipment must be regularly tested for microbiological germs. These pathogenic microorganisms pose a particular risk to food and can cause nausea, vomiting, or diarrhea in humans.

Hygiene in the healthcare sector

Hygiene plays a major role in the entire healthcare system, as around 18 million German citizens spend at least one night in hospital before or after treatment every year. Although hygiene standards in the German healthcare system are very high, around 600,000 people are still infected with germs in hospital every year.

These germs cause nosocomial infections, the consequences of which kill around 15,000 patients every year. Many studies have already shown that an improved cleaning program can curb MRSA infections, for example. MRSA infections are caused by bacteria that are resistant to antibiotics.

Our rapid tests can be used in any healthcare facility, as the patented A3 technology can be used to check surfaces for the presence of ATP+ADP+AMP.

Water disinfection for maximum hygiene

Germ-free, i.e. absolutely clean water, is required in many processes, especially in the food, chemical and pharmaceutical industries. The treatment of drinking water for germ-free industrial plants also plays a major role in water hygiene. The quality of the water used can affect the efficiency and reliability of an entire production process.

Water hygiene addresses all aspects of water supply and tests drinking water, bathing water, river water, industrial water and process water for impurities. The water analysis is carried out using special test methods that are used in central water supply systems, small systems, individual and in-house water supply systems and in water treatment.

Water is very sensitive and reacts to various external and internal influences. Suitable processes are used to remove microorganisms from the water, which are tested for beforehand at defined process points. The detection of coliform bacteria in water, for example, indicates a lack of hygiene. Alongside salmonella, these bacteria are therefore also considered a hygiene indicator.

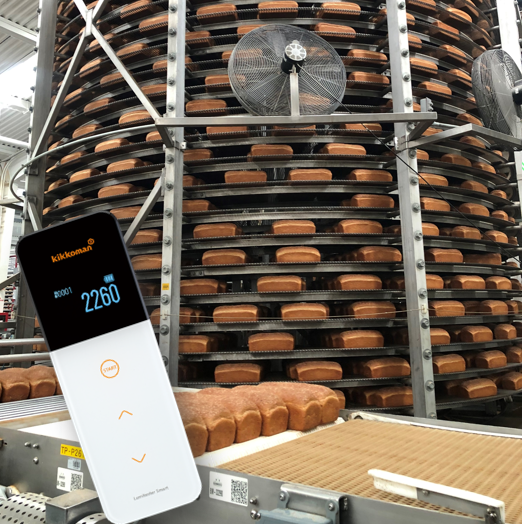

The Lumitester Smart

The Lumitester Smart allows for the rapid detection of microbial residues and food waste using the ATP method.

The A3 technology detects not only ATP (adenosine triphosphate) but also the lower-energy molecules ADP (adenosine diphosphate) and AMP (adenosine monophosphate). This represents a technological advancement over conventional ATP tests, as it significantly increases sensitivity. This is particularly important for heated and processed foods, since ATP is broken down into ADP and AMP during these processes and is undetectable with conventional tests.

- Reliable measurements within 10 seconds

- Unrivaled sensitivity

- intuitive operation and evaluation options via app / cloud service

- Cleaning validation according to HACCP

The Lumitester Smart from HyServe detects all organic residues and microorganisms on these surfaces as well as in liquids and determines the cleanliness level at the sampling point.