Limitations of conventional ATP Tests

Conventional ATP tests, while widely used in food processing for hygiene monitoring, suffer from a critical flaw: ATP's inherent instability, ATP, the molecule these tests detect, degrades rapidly into ADP (adenosine diphosphate) and AMP (adenosine monophosphate), especially in the presence of food residues. This degradation can occur even when substantial amounts of food soil, and therefore potential contaminants, remain on processing surfaces and equipment. This rapid breakdown of ATP leads to a significant challenge for quality managers: false-negative results. The surface may appear clean according to the ATP test, when in reality. significant contamination persists in the form of ADP and AMP. These false negatives can create a dangerous illusion of cleanliness, potentially leading to inadequate sanitation practices and increased risk of foodborne illness.

Recent Study by University of Wisconsin-Madison about ATP degradation

Research(1) has shown that ATP in raw meat degrades rapidly in processing environments, even when food soil is still present. A study comparing a standard ATP assay with Kikkoman A3, the only one that detects all three adenylates, in two meat processing facilities found that while both detected contamination at similar frequencies, the Kikkoman A3 assay detected significantly more contamination where ATP degradation was likely. Further research (2) indicated that ADP makes up about 90% of total adenylates in most meat processing stages, except the final cooking stage where AMP becomes the dominant adenylate. (Figure 1)

Figure 1. The change of ratios of adenylates at selected manufacturing steps during smoked sausage production in UW-Madison Meat Science and Muscle Biology Laboratory (ATP: Blue, ADP: Orange, AMP: Grey)

Retail processed meat samples were - further evaluated and they followed general trends of most having minimal ATP concentrations with ADP predominant in uncooked samples and AMP predominant in cooked samples.

Researchers from Wisconsin-Madison University recommend that facilities carefully consider these degradation phenomena when selecting a technology for purposes of hygiene assessment and verification.

Innovative technology: Kikkoman A3 provides a solution.

Kikkoman A3 can be a reasonable approach to avoid the effects of the ATP degradation phenomena, especially in meat processing facilities or where sensitivity to plant hygiene is especially critical. As it measures ATP, ADP and AMP, it gives you more accurate results in the validation of cleaning and sanitation processes during production of processed meat. This will increase your hygiene security and help to avoid cases of food born illnesses due to false-negative results in the validation of cleaning & sanitation processes.

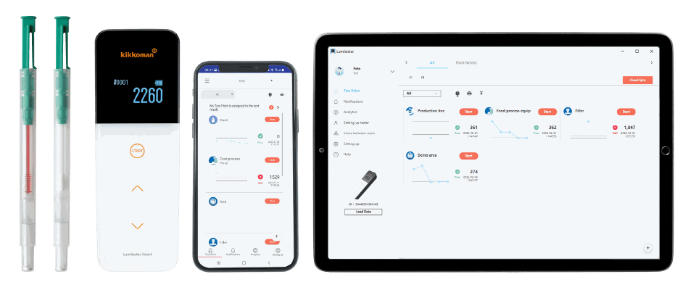

Step-up on your hygiene monitoring program by choosing the innovative technology of A3: Total adenylate measurement with Kikkoman A3 improving your hygiene monitoring.

In case you have any questions or need help implementing the new A3 program in your facilities, download the Kikkoman White Paper or contact us for a free of charge demonstration of how Kikkoman A3 can help to improve your hygiene management.

Robust cleaning and sanitation verification are cornerstones of effective food safety programs. While ATP testing has been a valuable tool, recent studies reveal a significant risk of false negatives due to ATP degradation, especially in meat processing. Consequently, food processors, particularly those handling meat, must carefully select hygiene verification technologies that prioritize accurate detection of residual soil to ensure process control and food safety. (3,4)

The Kikkoman A3 brings you a unique and powerful advantage. The Kikkoman A3 is the only system available that detects all three adenylates of ATP (ATP+ADP+AMP or "A3") all in one test providing better detection. Independent laboratory research confirms that Kikkoman A3 detects residues and microorganisms that other ATP assays miss.

1) Smith, N. W., J.J. Sindelar, S.A. Rankin 2019. Quantities of adenylate homologues (ATP+ADP+AMP) change over time in prokaryotic and Eukaryotic cells. J. Food Prot. 82: 2088-2093. https://doi.org/10.4315/0362-028X.JFP-19-223

2) Smith, N.W., J.J. Sindelar, S.A. Rankin 2024. AMP, ADP, and ATP concentrations differentially affected by meat processing, manufacturing, and non-meat ingredients, J. Food Prot. 87: 100287. https://doi.org/10.1016/j.jfp.2024.100287

3) Bakke, M. and S. Suzuki. 2018 Development of a novel hygiene monitoring system based on the detection of total adenylate (ATP+ADP+AMP). J. Food Prot. 81:729-737. https://doi.org/10.4315/0362-28X.JFP-19-223

4) Bakke, M. 2022. A comprehensive analysis of ATP tests: practical use and recent progress in the total adenylate test for the effective monitoring of hygiene. J. Food Prot. 85:1079-1095. https://doi.org/10.4315/JFP-21-384