Air and water are ubiquitous elements in food production facilities, yet they are often overlooked as potential sources of contamination. Considering them as essential "sub-ingredients" is fundamental for effective mold control and ensuring food safety. This article explores the risks of microbial contamination through air and water and highlights the importance of rigorous monitoring.

Recent industry incidents, such as mold contamination during the cultivation process that may have resulted in the production of undesirable compounds, have reignited the debate on the application of Good Manufacturing Practices (GMP) requirements and underscored the critical role of hygiene control in production environments.

The Importance of Air and Water Quality

Adequate ventilation, whether natural or mechanical, plays a vital role in minimizing airborne contamination, such as aerosols and condensation droplets. Furthermore, it helps regulate ambient temperature, control odors that can affect food suitability, and maintain humidity to prevent microbial growth and toxin production, especially in dry foods.

The World Health Organization (WHO) highlights the use of safe water and raw materials as one of the fundamental principles in its "Five Keys to Safer Food." The other keys include: maintaining cleanliness, separating raw and cooked foods, cooking thoroughly, and keeping foods at safe temperatures.

Practical Monitoring and Common Types of Mold

For practical mold monitoring, the use of surface and ambient air plates, such as DRBC or SDA (Sabouraud Dextrose Agar) agar, is recommended. It is equally important to monitor compressed air systems if they are used in direct contact with the product, according to GFSI/BRC/SQF requirements. Molds commonly found in food facilities tend to be sensitive to heat and dryness, unable to grow without oxygen, and are inhibited by refrigeration, being unable to develop when frozen.

Modern Detection Solutions

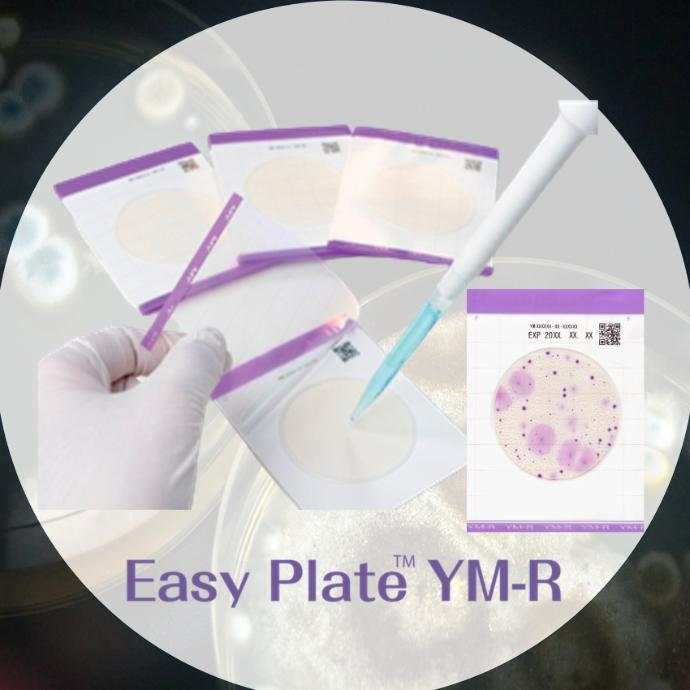

Practical alternatives to traditional monitoring methods include the use of rapid, ready-to-use culture media. The Easy Plate™ series from Kikkoman Biochemifa, for example, offers plates like Easy Plate AC (for aerobic count) and Easy Plate YM-R (for yeast and mold count). For self-monitoring of water and liquid quality, tools such as LuciPac A3 Water (ATP test for liquids) and the LuciPac A3 Microbial Detection Kit for Liquids are available.

Conclusion

Effective mold control in the food industry requires a holistic approach that recognizes air and water as critical components of the production process. By implementing robust ventilation practices, regular monitoring, and utilizing modern testing tools, food manufacturers can significantly reduce contamination risks, ensuring the safety and quality of their products.

Literaturverzeichnis

- Kikkoman Biochemifa Company. (2025, 26 de maio). Mold Control in Food Manufacturing: Air and Water Are Crucial “Sub-Ingredients”. Kikkoman Biochemifa Company. https://biochemifa.kikkoman.com/e/kit/article/article_detail_329/

- Food Safety Authority of Ireland. (n.d.). Moulds and Food Safety. FSAI. https://www.fsai.ie)

- Pieter-Jan Loveniers, Frank Devlieghere, Imca Sampers, Towards tailored guidelines for microbial air quality in the food industry, International Journal of Food Microbiology, Volume 421, 2024, 110779, ISSN 0168-1605, https://doi.org/10.1016/j.ijfoodmicro.2024.110779.

- Wujie, Zhufei, Xujing, The Influence of Water Quality on Food Quality and the Treatment of Water for Food Processing, Procedia Environmental Sciences, Volume 10, Part C, 2011, Pages 2671-2676, ISSN 1878-0296, https://doi.org/10.1016/j.proenv.2011.09.415.

- World Health Organization. (2006). Five Keys to Safer Food manual. Geneva: WHO. Recuperado de https://www.who.int/publications/i/item/9241594632

- Codex Alimentarius Commission. (2023). General Principles of Food Hygiene (CXC 1-1969). FAO/WHO.